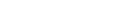

MBVT-1100/MBVT-1300

Unit

MBVT-1100

MBVT-1300

Work Table

| Working table size | in | 147.244 x 24.015 | 59.055 x 27.952 |

| T-slots (Size x Qty x Dist.) | in | 0.708 x5x3.937 | 0.708 x5x5.511 |

| Max .table load | lb | 1,763.698 | 26,45.547 |

Travel

| X axis travel | in | 43.307 | 51.181 |

| Y axis travel | in | 25.59 | 27.559 |

| Z axis travel | in | 24.015 | 24.015 |

| Spindle nose to table surface | in | 5.905~27.952 | 5.905~29.921 |

Spindle

| Transmission | Belt Drive | ||

| Spiindle taper | BT-40 | BT-40 | |

| Spiindle speed | rpm | 8,000 | 8,000 |

| Spindle motor | hp | 14.955/20.394 | 14.955/20.394 |

Feed

| X-Y-Z motor ( Fanuc) | hp | 4.078/4.078/4.078 | 4.078/5.438/5.438 |

| X-Y-Z motor ( Mitsubishi) | hp | 34.758 /34.758/34.758 | 34.758 /34.758/34.758 |

| X-Y-Z rapid travel | ft/min | 78.74/78.74/59 | 78.74/78.74/59 |

| X-Y-Z cutting feed rate | ft/min | 32.8 | 32.8 |

ATC system

| ATC type | Arm type | ||

| Magazine capacity | pcs | 24 | 24 |

| Max . tool diameter | (in) | 3.937 | 3.937 |

| Max . tool length | in | 11.811 | 11.811 |

| Max. tool weight | lb | 22.046 | 22.046 |

Rail Type

| 3-axes raill | X-Y-Z boxways / Y-axis 4 guideways | ||

General

| Power comsumption | KVA | 20 | 20 |

| Air pressure | kg/cm2 | 6 | 6 |

| Floor occupation | cm | 151.574x141.732x118.11 | 151.574x141.732x118.11 |

| Machine weights | lb | 18,077.9 | 18,739.29 |

The builder reserves the rights to modify the design, specifications, ect. to improve the performance of machines when necessary.

- The major construction parts are based on super strong cast iron, which are stable and precision-proved in structure.

- Wide base & box-shaped column/enhanced saddle and full supported workpiece structure all contribute to the ability for heavy duty machining

- Super strong design on column provides the best heavy cutting rigidity. The lead-guide for counterweight ensures no vibration effect when Z axis moving and cutting.

- 4-guideway design on Y axis ensures the machine free from loads deformation which guarantees the reliability and repeatability accuracy while machining.

GEAR-DRIVE SPINDLE

The geared-head spindle performs increased high torquefor heavy duty cutting. All the gear parts are containedin oil box with well-sealed system to guarantee all partesbeing lubricated well and make the noise down to low level.

DIRECT-DRIVE SPINDLE

The most advanced spindle design is an innovative

10,000~12,000rpm, in-line direct-dirve spindle that is coupled directly to the motor. This provides super-smooth operation for excellent surface finishes, and reduces operating heat for greater thermal stability.

CARTRIDGE TYPE SPINDLE

The spindle uses pre-loaded angular contact bearings

throughout to enhance radial stability, enabling heavy cuts in steel. The belt type spindle allows heavier cutting and create a better part finish.