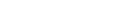

MHT 500 Series

Hi-Speed Horizontal Machining Center

Model

HT-500A

HT-500B

Travel

| X-axis travel | 31.496 in | |

| Y-axis travel | 31.496 in | |

| Z-axis travel | 31.496 in | |

Rotary Table

| Working tablel | 19.685 x 19.685 in (opt. 19.685 x 24.803 in) | |

| The maximum load of working table | 1322.773 lb | |

| Minimum indexing degree | 0.001 ° (opt.: 1 °) | |

| Surface configuration | M16 x 0.078 in x 1.299 x 3.937 in | |

| Rotary time | 3.6 sec/rev | |

| Cutting force resistance | 551.155 lb-m | |

Spindle

| The distance from spindle nose to Working table surface Working table surface |

5.905 ~ 37.401 in | 5.314 ~ 36.811 in |

| The distance from spindle center To table surface |

4.724 ~ 36.22 in | |

| Spindle nose taper | BT-40, 7/24 No. 40 (Opt. HSK-A63) | BT-50, 7/24 No. 50 |

| Spindle speed | Built-in : 10,000 rpm(Opt. 12,000, 15,000 rpm) | Built-in : 6,000 rpm(Opt. 8,000, 10,000 rpm) |

| Spindle diameter | 2.755 in | 3.937 in |

Feed

| Rapid feed(X/Y/Z) | 118.11/118.11/118.11 ft/min (Opt. 196.85/196.85/196.85 ft/min) | |

| Cutting speed | 32.808 ~65616.797 ft/min | |

ATC

| Tool change method | Arm | |

| ATC drive | servo motor | |

| Magazine drive | servo motor | |

| Tool shank | BT-40 (Opt. HSK-A63) | BT-50 |

| Tool capacity | 40T (Opt. 60T) | |

| Tool change time | T-T 1.5 sec, C-C 4, 5 sec | T-T 3sec, C-C 6 sec |

| Pull stud | MAS 403 P40T-1(45 °) | MAS 403 P50T-1(45 °) |

| Max .tool diameter(with adjacent tool) | 3.74 in | 4.921 in |

| Max .tool diameter(without adjacent tool) | 7.874 in | 9.842 in |

| Max .tool length | 15.748 in | |

| Average tool weight | 11.023 lb | 22.046 lb |

| Max. tool weight | 24.25 lb | 44.092 lb |

| Tool selection method | fixed position | |

APC

| Exchange method | rotary pallet change | |

| Number of pallets | 2 | |

| Max. jig swing diameter | Φ 29.527 in | |

| Max .jig height | 35.433 in | |

| Pallet surface to floor | 45.275 in | |

| Pallet exchange time | 11 sec | |

| Positioning | VDI 3441 P0.014mm (JIS B6338 ±0.004 /300 mm) | |

| Repeatability | VDI 3441 PS0.010mm (JIS B6338 ±0.003 mm) | |

Motor

| Spindle motor | FANUC 25.152 /29.911 hp (cont. /15 min) MITSUBISHI 25.152 /25.152 hp (cont. /15 min) |

|

| Servo motor X/Y/Z/B | FANUC X : 7.477 hp, Y : 7.477 hp , Z : 7.477 hp, B : 2.719 hp | |

| Magazine motor | FANUC Absolute, With brake MITSUBISHI : absolute with brake |

|

| ATC motor | FANUC : Absolute MITSUBISHI: Absolute |

|

| Coolant pump motor | 0.503 hp | |

| Hydraulic unit motor | 5.03 hp | |

General

| Power capacity | 45kVA | |

| Pressure capacity | 3~4 kg/cm2 (0.3~0.4 MPa) 220 L/min | |

| Mechanical dimensions(WxDxH) | 12.204 x 24.015 x 11.811 in | |

| Machine weight | 29762.405 lb | 30864.716 lb |

The builder reserves the rights to modify the design, specifications, ect. to improve the performance of machines when necessary.

- High-tensile Meehanite cast iron on all major pars, with 3 layer T shape box type one-piece base design provides best rigidity and superior accuracy stability.

- Multi-layers and enforce=rib design on base unit structure prevent any deformation and greatly reduce machining vibration during high speed operation.

- All three axes equipped with C3degree 45 mm extra wide high accuracy linear guide way and high precision hollow coolant through ballscrew to ensure machining situation under very stable status

- Main structure design adopts FEM technology to create a superior rigid and accuracy during high speed operation.

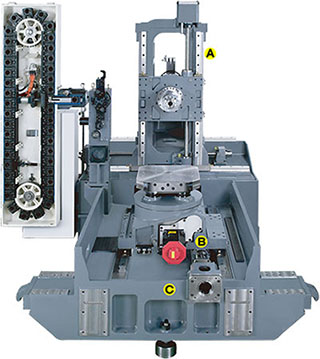

STRONG COLUMN

Thick and solid double framed wall

and consolidated rib designs make

great rigidity and reduce the out of

shape caused by heavy cutting,

ensuring long-period machining

accuracy.

and consolidated rib designs make

great rigidity and reduce the out of

shape caused by heavy cutting,

ensuring long-period machining

accuracy.

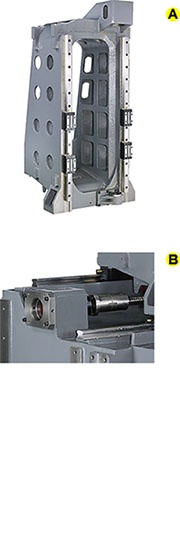

SUPERIOR HIGH SPEED

AXIAL FEEDRATE

AXIAL FEEDRATE

Φ17.716" P20 coolant through ball

screw design on all 3 axes provides

highest rapid feed rate 196.85 ft/min

with minimum heat deformation

during high speed operation.

screw design on all 3 axes provides

highest rapid feed rate 196.85 ft/min

with minimum heat deformation

during high speed operation.

LARGE SPAN DESIGN

28.346" extra wide span between Z

axis slides provides most stable

movement and heavy machining

operation support.

axis slides provides most stable

movement and heavy machining

operation support.